7 Things to Think About When Making Your Own Stickers

Everyone loves stickers. They’re not just a popular and versatile tool for businesses, they’re also a form of self-expression. They can reveal a great deal about ourselves like our favorite kind of music, quotes and sayings that we relate to, the teams we support, and even our political ideals.

Whether you want to make stickers to promote your brand, spruce up products, or just for plain fun, there’s a wide variety of options you need to consider as you start your custom sticker printing journey.

Cut-to-Size, Roll, or Sheets?

To make stickers, start with the sticker format that fits your requirements. Stickers come in three (3) types: cut-to-size, roll, and sheets.

Cut-to-size stickers, also known as individually cut stickers, are cut in singles according to their specified shape and size and delivered in stacks. These are printed on an easy crack-and-peel backing for easy application. Cut-to-size stickers are widely used for promotions and giveaways, and suitable for low-quantity sticker applications.

On the other hand, roll stickers are perfect for high-quantity orders and rapid application in production lines. The stickers are printed on the adhesive and wrapped around a spool so they’re easier to peel and dispense.

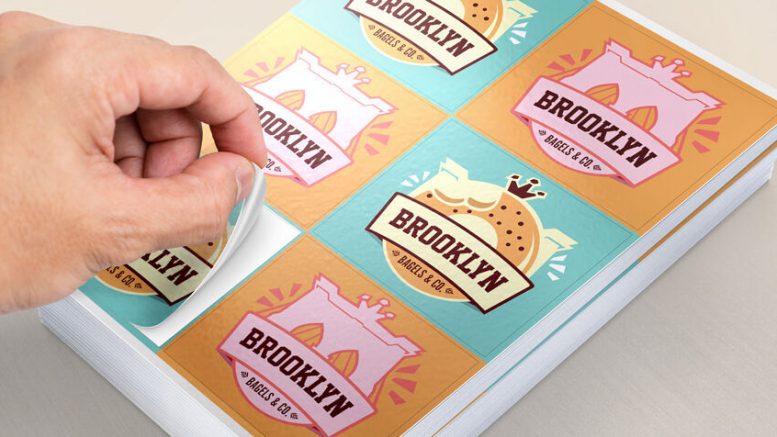

Sheet stickers are printed on 8.5” x 11” sized adhesive papers, which makes them easier to stack and store. We only cut through the sticker and not through the backing. This allows you to peel the stickers individually off the sheet. Sheet stickers let you print several designs on a single page.

Location

Think about how your stickers will be applied. Will they be applied indoors? Do you want customers to use them on car windows and laptops? Do they need to be waterproof? How large is the space available for your stickers? This helps figure out what material and size will work for you.

Materials and Finishes

With the location in mind, certain adhesives and coatings also have a specific visual effect and impact the longevity of your stickers.

White vinyl is often used for sticker giveaways because of its durability. It has a weatherproof and UV-resistant high-gloss coating that adds vibrance and emphasizes detail in designs. Biaxially-oriented polypropylene (BOPP) is made of plastic-like film that is suitable for outdoor use. Aside from being water-resistant, BOPP offers unique design opportunities as it comes in transparent, white, and metallic options.

For classic and eco-friendly brands, uncoated white sticker paper or textured Estate adhesive is often preferred because of its natural texture. Choose your sticker finish with care, as this will either emphasize or understate your design.

Resolution

As you work on your sticker designs, keep your image resolution at least 300 dpi or higher. Stickers should be clear even from a distance, and a high-resolution file ensures they print nicely without any pixelation.

Shape

Your chosen shape should not only match your design but also add visual interest to your stickers. Rectangle is the most popular shape because it provides more space to include graphics and text. Square stickers are perfect for promotional stickers with logos and often used as product labels as well. Try rounded corners for a more unique look. Oval and circle are suited for minimalist designs that need to draw attention to the center of the artwork. To stand out, try custom shapes. These are perfect as handouts and giveaways at events. Custom shaped stickers let you create any design and PrintRunner can trim the sticker according to its exact shape.

Colors

Choosing colors that match your brand and style is all well and good, but you should also consider how these colors go on your preferred sticker material and finish. For example, vivid designs are better off printed on a solid opaque background like white vinyl, as clear BOPP might wash it out. Matte coating can add a chalky appearance to brighter hues and soften the tones for a more modern effect. On the other hand, gloss will amplify the colors and make them pop. All these important aspects will help you make the most out of your sticker printing.

Proofing

One of the advantages of custom sticker printing is getting help from printing experts. Professional printing services include proofing artwork so your stickers will come out exactly as you want. PrintRunner offers free design reviews that include checking your format and design elements according to our technical guidelines before we print your order.

Make stickers with PrintRunner today. If you have questions, call us at 1-888-296-5760 and our customer care representatives can assist you.

Frequently Asked Questions

How do I make stickers?

Designing and printing stickers is easy on the PrintRunner website. Just use the order calculator to choose the type of sticker, size, material, and quantity. Be sure to include your preferred printing turnaround time. After, just upload your own design file or click Design Online to make one from scratch.

How long does it take to print stickers?

This depends on your printing turnaround options. You can check what options are available for your type of sticker using the product page order calculator. Our fastest printing turnaround time for stickers in one (1) business day. Note that the turnaround time does not include shipping transit time, weekends, and holidays. You can check the Estimate Shipping Date on the online calculator. This will show the transit time based on your ZIP code.?

What sticker material should I choose?

This depends on where you’ll use the stickers. Sticker paper our most popular material indoor application. If you need something more durable, white vinyl and BOPP are waterproof and suitable for outdoor application.

How much does it cost to print stickers?

The price depends on your sticker quantity, size, and material. Generally, the more stickers you order, the lower the cost per piece. To get an instant quote, just select your preferred sticker specifications on the order calculator and the website will automatically generate the estimated price.

How much does it cost to print stickers?

The price depends on your sticker quantity, size, and material. Generally, the more stickers you order, the lower the cost per piece. To get an instant quote, just select your preferred sticker specifications on the order calculator and the website will automatically generate the estimated price.

Related Articles: